We have managed to build up a lot plastic trash that it is daunting to consider what may very well be carried out with the tons upon tons of nonbiodegradable waste. And as a lot as we are attempting to cut back our dependence on single-use plastics, we proceed so as to add to the worldwide plastic trash hoard.

Occasions just like the COVID-19 pandemic solely served to broaden their use for private protecting gear and disposable and take-away packaging.

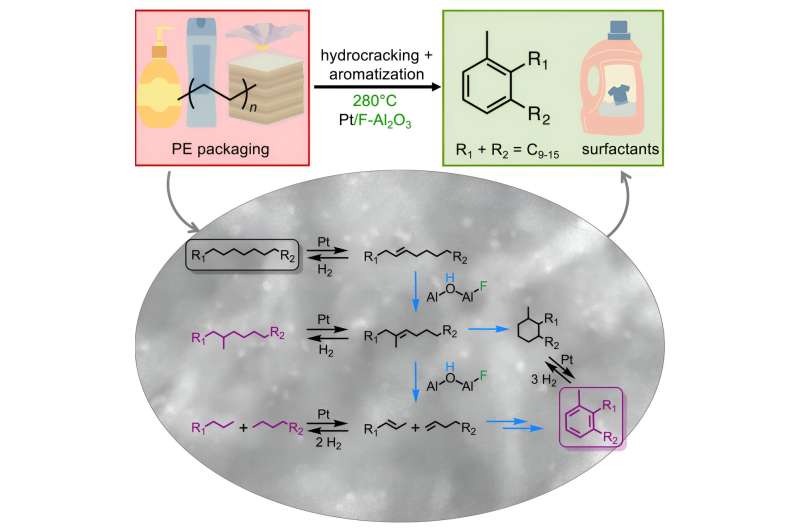

However, for researchers at College of California Santa Barbara, one particular person’s single-use packaging is one other particular person’s helpful uncooked materials. In a paper revealed within the journal Chem they’ve reimagined the worth of single-use plastics, with enhancements to an revolutionary course of that may flip polyolefins, the commonest kind of polymer in single-use packaging, into worthwhile alkylaromatics—molecules that underlie surfactants, the principle elements of detergents and different helpful chemical compounds.

“If we make these surfactants from fossil fuels now and you could possibly make them from waste plastics, then you aren’t utilizing fossil fuels to make surfactants anymore, and also you’re getting one other use out of the carbon that went into the plastics,” mentioned chemical engineering professor Susannah Scott, who holds UCSB’s Mellichamp Chair in Sustainable Catalytic Processing.

As an alternative of burning them or burying them in landfills—practices that characterize the most important methods we at present cope with plastic waste—plastics are repurposed in a way that shortcuts typical “soiled” processes for making surfactants whereas giving single-use plastics yet another shot at usefulness.

The researchers constructed on earlier work during which they debuted a catalytic methodology to interrupt the robust carbon-carbon bonds that make plastic the difficult-to-degrade materials it’s, then rearrange the molecular chains into alkylaromatic rings. Whereas efficient, Scott mentioned, the unique course of, primarily based on a platinum-on-alumina catalyst, was sluggish, and its yield of alkylaromatic molecules was low. “What we have carried out on this paper is present easy methods to do it significantly better,” she mentioned.

Key to their methodology is growing the acidity of the unique alumina catalyst, through the addition of chlorine or fluorine. With the added acid websites, the workforce was in a position to increase the pace and selectivity of their course of.

“It simply screams alongside,” Scott mentioned. “It makes the alkylaromatics quicker, and we will tune it to make the right-size molecules.” Within the new paper, they targeted on discovering the optimum ratio of acid websites to steel websites of their catalyst, she defined. “It seems they work collectively. They’ve completely different roles, however you want each of them to be there and in the best ratio so the catalytic cycle would not get caught at any level.”

As well as, their one-pot course of operates at average temperatures, requiring a low vitality enter. Whereas the tactic initially took 24 hours to show plastic into alkylaromatic molecules, the improved course of can full the duty inside a few hours, growing the quantity of plastic that may be transformed in a reasonably-sized reactor.

With additional enhancements, this methodology may very well be on its technique to turning into a viable business course of, in response to Scott. The final word purpose is to carry it into vast use, which might allow and incentivize the restoration of single-use plastics. Utilizing waste plastics as a extremely plentiful uncooked materials, chemical firms might take the alkylaromatic molecules ensuing from this course of and rework them into the surfactants which are formulated into soaps, washing liquids, cleansers and different detergents.

“Ideally you need to reuse waste plastic for a function with a big sufficient manufacturing quantity, for which there’s important demand, with a purpose to make a dent within the plastic downside,” Scott defined. To find out if this methodology is really sustainable, she added, it must endure a lifecycle evaluation, during which the vitality spent and greenhouse gases emitted are calculated at every step.

Utilizing waste materials ensures that no further greenhouse fuel emissions are produced to create the feedstock, however the vitality required to run the catalytic course of and separate the specified molecules must be factored in earlier than scaling up, Scott mentioned. If it passes muster, the tactic might displace the extra fossil fuel-intensive processes that go into creating surfactants from scratch.

“We are going to want a number of targets to cope with the waste plastic downside, however it is a pretty massive one,” Scott mentioned. “That is value doing.”

Extra data:

Jiakai Solar et al, Bifunctional tandem catalytic upcycling of polyethylene to surfactant-range alkylaromatics, Chem (2023). DOI: 10.1016/j.chempr.2023.05.017

Journal data:

Chem

Supplied by

College of California – Santa Barbara

Quotation:

Plastic waste can be utilized as uncooked materials for detergents, due to an improved catalytic methodology (2023, August 17)

retrieved 20 August 2023

from https://phys.org/information/2023-08-plastic-raw-material-detergents-catalytic.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.